New York was founded at the beginning of the 17th century, to be precise in 1624. Since then, the city has actively developed as a commercial port, a center of trade, and a hub for strengthening Dutch and later English influence in the new lands. This continued until the beginning of the War of Independence. During this period, New York became the first capital of the United States. Afterwards, the city simply grew as a port, cultural, financial, political, trade and industrial center. This has continued up to the present day. By the beginning of the 21st century, industries such as chemical, machinery, textile and food had developed in the city. But what about the metallurgical industry? Did you know that there was a time when New York was a metallurgical center of the country? Specifically, one of the large factories, called Mott Iron Works, was located in the Bronx, which was a metallurgical plant. If you didn’t know that, we suggest you familiarize yourself with interesting information about this enterprise at bronx 1.one website.

The history of the company’s establishment

As the publication waltergrutchfield reports, if you enter the search term “Mott Iron Works” into a search engine, it will immediately offer you information about the establishment of Jordan L. Mott’s enterprise in 1928 in the Bronx. You will also receive a few other well-known facts. Overall, it will take about five minutes to read. However, if you delve deeper into this topic, it turns out that everything is much more interesting.

It’s worth starting by mentioning that Jordan L. Mott was an American inventor and entrepreneur. His father was a public official and industrialist in New York. Though he began his life as a grocer, the son not only took over his father’s foundry business but also improved it, as he had numerous ideas for metallurgy. In particular, he invented a new device for separating various materials, which was used by paper and textile manufacturers. At the time, they burned wood, so when Mott invented a kitchen stove that could be safely loaded with anthracite coal, it significantly reduced household expenses. He is also the inventor of the hydraulic press, which compressed materials for making paper or compressing metal parts. His next popular invention was a screw pump for marine transportation. He also improved water wheels (which were used in the textile industry, mills, and river navigation). Therefore, there was a lot to produce, and Jordan L. Mott initially built a small foundry near his store on Water Street in Manhattan. With time, there were so many orders that he had to purchase land to build a factory.

Construction of a factory

The enterprise was built in the Bronx, on the Harlem River, at 134th Street. The site was adjacent to the Harlem Bridge, and there was a canal nearby that could be used to transport materials. The land was purchased from the Morris family, who had owned it for a long time and were also government officials. The cost of the land for the plant was $175 per acre. A house, or rather a residence, was built near the plant. A settlement for workers was also established nearby.

How the factory operated

The construction of the factory was carried out in parallel with the production of goods. The first foundries were made of wood, so they often caught fire. However, they were rebuilt again and again, becoming bigger each time. During one of the fires, while firefighters were extinguishing the flames, Jordan L. Mott and the workers were constructing another workshop.

The size of the factory was significant. According to the 1850 census, Jordan L. Mott employed 4 workers who earned $186 per month. The company produced pipes and plates. Other sources report that 40 workers were employed, earning a total of $960 USD.

His business was so successful that by 1871 its value amounted to 1 million dollars. By that time, the factory was already being managed by Jordan L. Mott’s son – Jordan L. Mott Jr.

What did the Mott Iron Works factory produce?

The factory existed for almost 100 years and during this time became famous for its diverse products. Let’s name some well-known high-quality iron products from the Mott Iron Works:

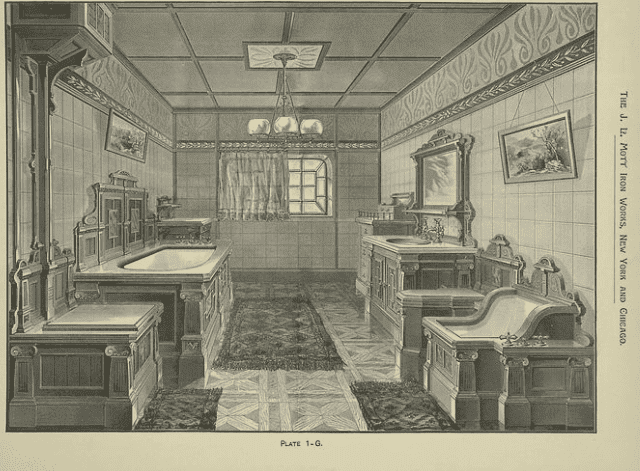

- The first one is ornamental forging. The enterprise was known in the country for its high-quality, smooth handrails, lanterns, fences, grilles and gates. These products were often used to decorate buildings and other structures.

- Secondly, there are fireplace grates. They were durable and aesthetically appealing. They were convenient to use to prevent coal and ash from falling onto the floor.

- The third type is the suspended pallets. These products were installed under bathtubs and sinks.

- The fourth thing is fire hydrants that had a nice design, an inverted letter “Y”, and became popular worldwide.

- Fifthly, the factory produced high-quality stoves for kitchens, as well as fireplaces, industrial ovens and fans for the latter.

- The last fact is that enterprise was one of the country’s leaders in the production of wheels, bodies and railway tracks.

Moving and closure

The factory successfully operated for over half a century thanks to the genius of Jordan L. Mott, who tirelessly came up with and implemented new and high-quality products in production. Only his death prevented him from continuing to amaze his contemporaries with his masterpieces. Unfortunately, his son and grandson were not as lucky.

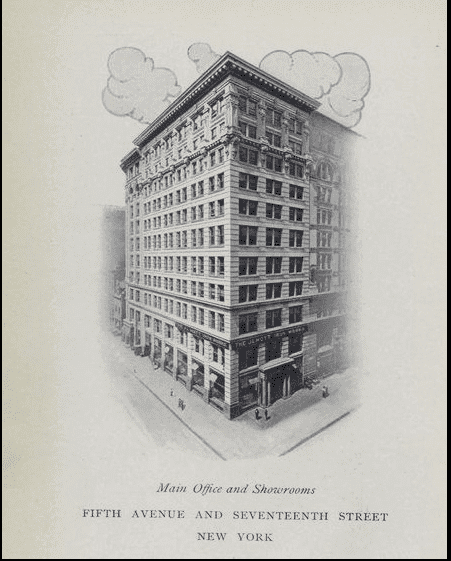

In 1902, The New York Times published an article with the headline stating that the “Mott Haven Plant to be Abandoned.” The article mentioned that a new location was planned for the plant, where seven new buildings were to be constructed. The reasons for the move were unknown, but it is assumed that financial difficulties or a desire to be closer to sources of ore may have played a role. The new location was decided to be Trenton, a city in the state of New Jersey, and preparations began for the move. These preparations included the construction of new factory buildings at the new location before the equipment could be transported, which was estimated to take 12 months.

In Trenton, which was one of the centers of rubber production in the USA at that time, it was planned to construct 7 new buildings. The first one was a 500-foot foundry. Then an electric power station was to be built to power the production and provide lighting for the workers’ premises. Its plan was almost ready. The construction was set to begin on August 1, 1902. Other buildings were also planned, among which an important place was occupied by a single-story enameling workshop that was supposed to be 300 feet long. The plan was to combine the machine and copper workshops in one building, which was to consist of 4 floors and have a basement. Two more buildings were planned to be smaller than the others.

On the eve of the announcement of the Mott family’s relocation, their agents were buying property in Trenton to house the factory and its workers. Only after this was the deal itself announced. It was also rumored that the construction of the new factory had cost one million dollars.

So, the factory relocated to a new location and continued to operate there for some time. According to some sources, it ceased operations in the 1920s, while others indicate it was in the 1940s. Today, the factory’s site in both the Bronx and Trenton is a historic landmark of these cities, serving as a reminder of the industrial might of the United States during that era. What do you know about Jordan L. Mott and his enterprise in the Bronx? Share your thoughts in the comments.